Guide to files, grinding and saw blades in jewelry making

Share

Creating jewelry requires precision and careful work, where the right tools make a big difference. In this guide, I will go over the different types of files, abrasives and saw blades used in jewelry making, as well as their different grits.

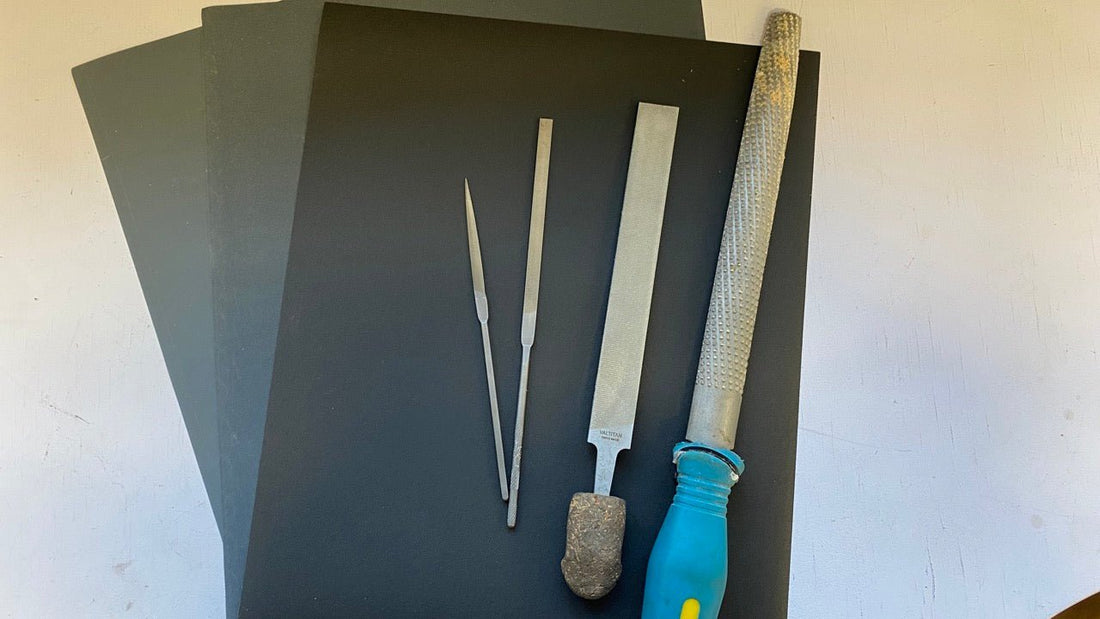

Files

Files are used to shape, smooth and fine-tune metal surfaces. They come in different coarsenesses and shapes depending on the job.

Roughness scale

Files come in different grades from coarse to fine on a scale from 00 to 6, where lower numbers are coarser and higher numbers give a finer finish.

| Heaviness | Description | Use |

| 00 - 0 | Very rough | For fast material removal. |

| 1 - 2 | Medium coarse | Good for basic shaping. |

| 3 - 4 | Finer | For detail work and surface improvement. |

| 5 - 6 | Very nice | For final surfaces and high finish. |

Common file types

Approach file

A larger and more stable file with straight edges used for making flat and even surfaces and sharp corners. Perfect for working with larger pieces of metal and rough shaping.

Needle file

Small and thin files available in various profiles (flat, round, triangular, etc.) and used for fine adjustment and detailing in tight spaces. Ideal for shaping small components and decorative elements.

Jewel file

A fine and narrow file with high precision, often with a very fine cutting surface. Used for careful finishing and finishing of jewelry to obtain a smooth and even surface.

Different cuts

Single-cut file

Has a single series of parallel teeth and is used to create a smooth and smooth surface.

Double-edged file

Has cross-set teeth that provide a more aggressive cut and are good for quickly removing material.

Rasp

Has coarse, spread teeth and is used for very rough processing, often on soft materials such as wax and wood.

Diamond file

Has an abrasive surface coated with diamond particles and is ideal for hard materials such as stone and ceramics.

Abrasive material

Abrasive materials are used to refine surfaces and prepare jewelry for polishing.

Sandpaper

Available in different grain sizes (grit numbers) where a higher number means a finer surface.

| Grit | Description | Use |

| 150 - 400 | Bearish | Remove scratches and rough unevenness. |

| 600 - 1000 | Medium | Provides a smoother surface and prepares for polishing. |

| 1200+ | Nice | Creates an almost mirror-like surface. |

Grinding wheels and polishing discs

- Silicone/rubber sanding discs – Removes scratches and creates a fine finish.

- Polishing discs with polishing paste – Used for high-gloss final polishing.

Saw blade

Saw blades are used in jeweler's saws to cut metal and other materials with great precision.

Roughness scale

Saw blades are numbered based on thickness and density of teeth:

| Scale | Use |

| 4/0 - 8/0 | Thin blades for detailed cuts in thin metal. |

| 2/0 - 1 | Medium blade for general work. |

| 2 - 6 | Coarse blades suitable for thicker metal and fast cuts. |

Summary

Choosing the right file, abrasive and saw blade is crucial for a professional end result in jewelry making. A coarse file or abrasive is used to quickly remove material, while finer tools help create a smooth and polished finish. With the right combination of tools, the process is both efficient and enjoyable!

Good luck with your jewelry creation!